- ABOUT

- BRANDS

- PRODUCTS

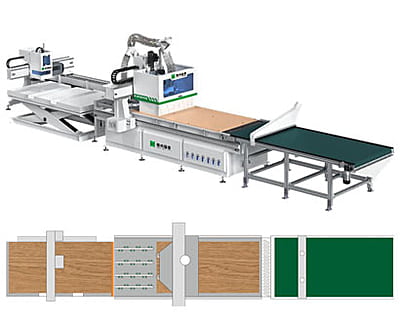

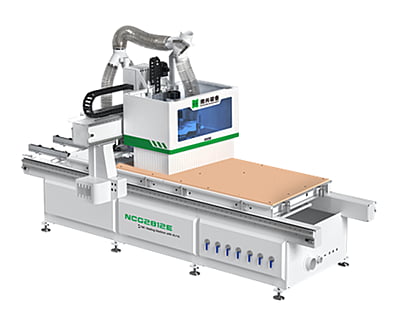

- Woodworking Machines & Consumables

- Laser Marking & Cutting Machines

- Power Tools & Hand Tools

- Sawing

- Portable Edge Banding Machine

- Drilling & Screwdriving

- Portable Jointing Machines

- Woodworking and Metalworking Clamps

- Hand Planers & Portable Thickness Planers

- Hand Routers & Trimmers

- Surface Finishing Tools

- ACP Fabrication Tools

- Drywall Construction Tools

- Multi Tool Oscillators

- Workplace Organisation

- Metal Working Power Tools

- Portable Dust Extractors

- Dust Collection & Pollution Control Equipment

- Paint Booth, Spraying Machines and Clean Rooms

- Material Handling Equipment

- Air Compressors, Purification & Pneumatics

- Packaging Machines

- Power Related Equipment

- Aluminium & uPVC Fabrication Machines

- Second Hand Machinery

- Interior Solutions

- PACKAGES

- More

Currency

0