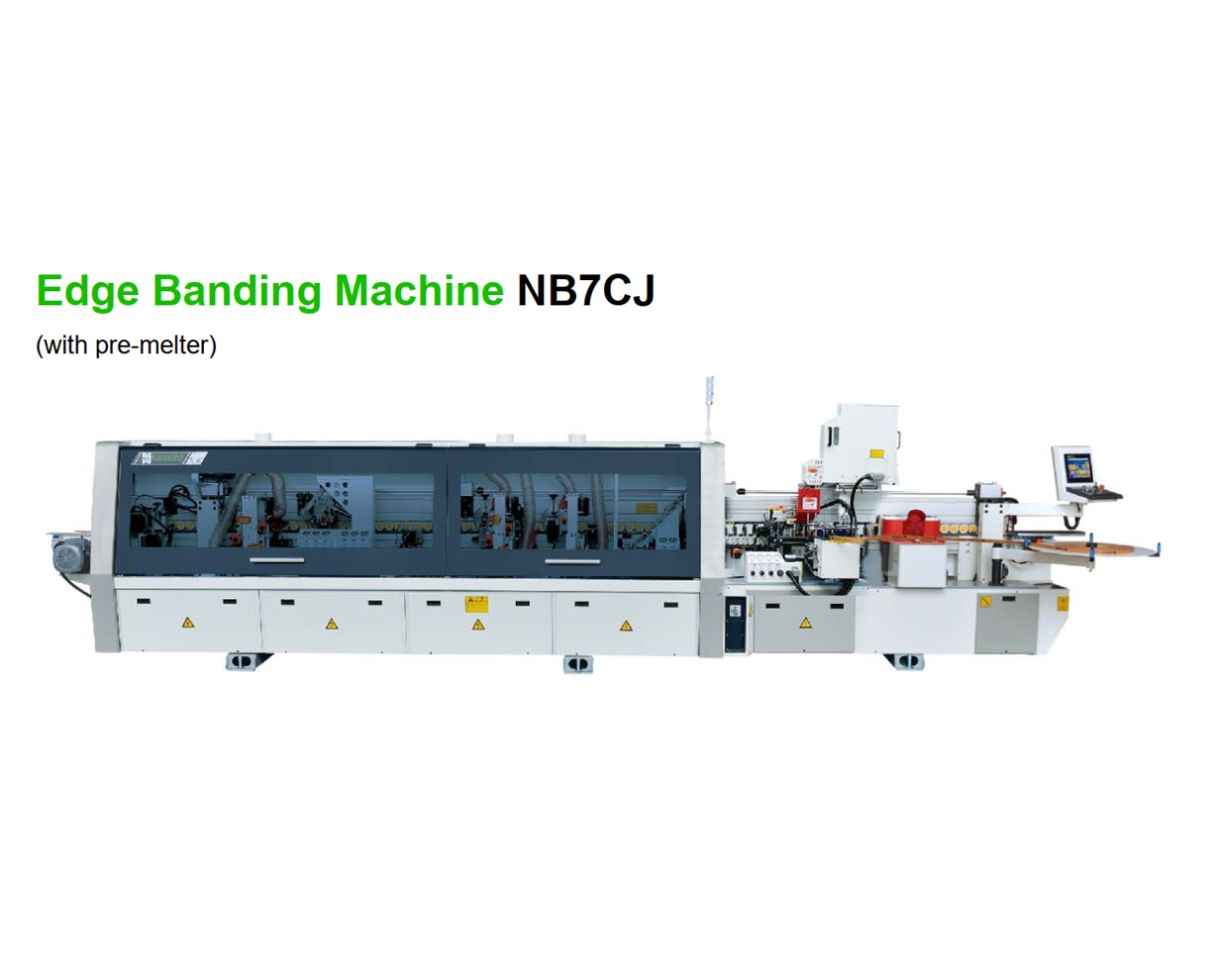

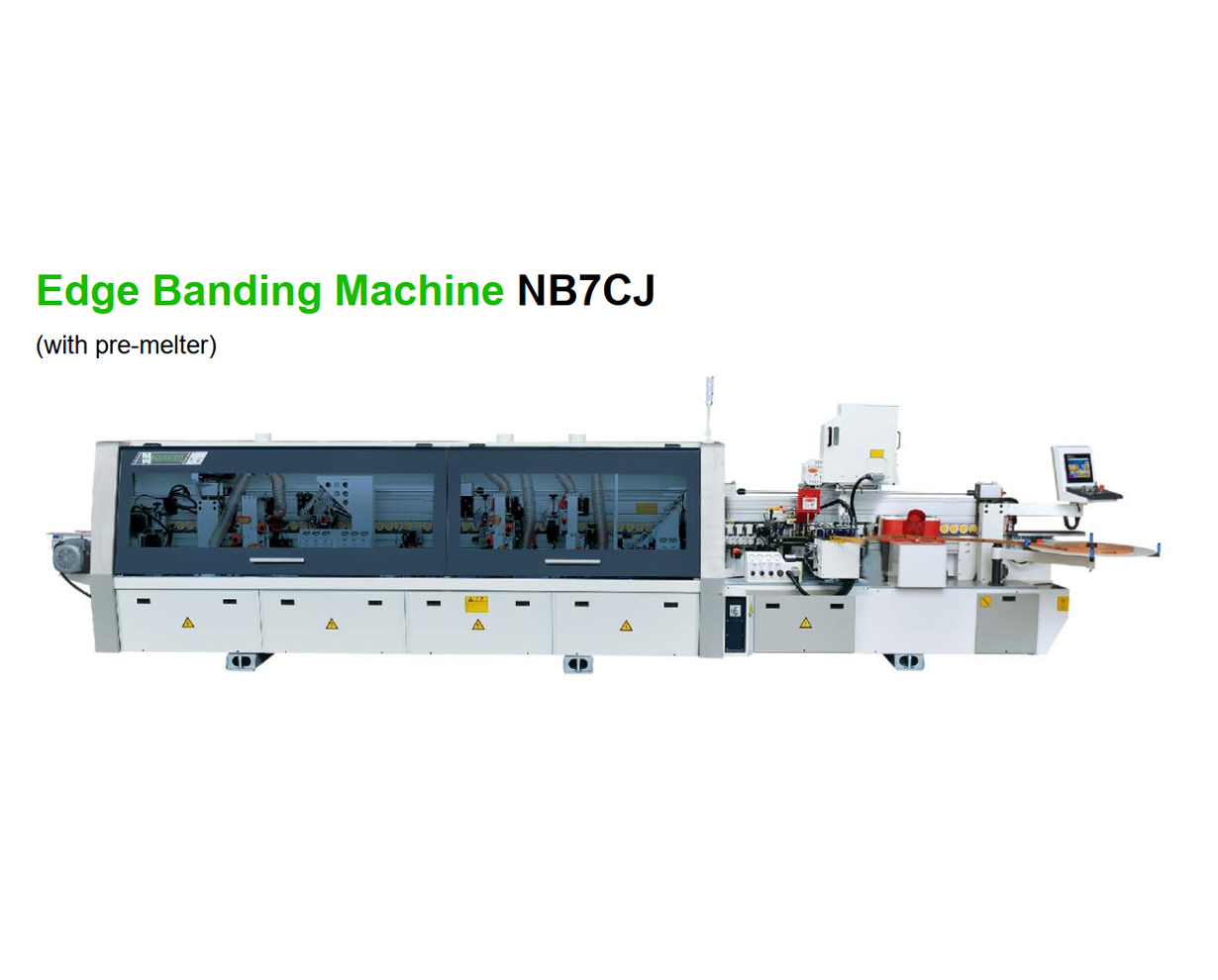

Nanxing Edge Banding Machine with Premelt+Cleaning Units NB7CJ(1Pre-Melt) (415V)

The Nanxing Automatic Edge Banding Machine model NB7CJ integrates various processing and operational units into a single continuous process to complete the edge banding work. This Edge Banding Machine merges the following functions:

FEATURES:

Pre-milling

Spraying device (release+ cleaning agent)

Pre Heating

Pre-melter gluing system

Snipping End Cutting

Pressure Rollers

Lubrication System

End Trimming

Rough Trimming

Fine Trimming R1.5 Cutter with pneumatic auto tools adjustment

Corner Trimming R1.5 Cutter

Scraping unit with 2 position pneumatic auto adjustment.

Buffing

Safety device Feeding Protector Safety Device

Safety device Interval feeding detection system

Safety device E-Stop

Remote switch & Indicator light

Energy Saving quick start/stop in one click

Controll System 10" touch screen

TECHNICAL SPECIFICATIONS:

- Panel length : 120mm

- Panel width : 80 mm

- Mini. Panel size : 120x80mm

- Panel thickness : 10-60 mm

- Edge tape thickness : 0.4 - 3 mm

- Feeding speed : 16/20/24 m/min

- Power supply : 415 V; 50 Hz

- Air pressure required : 0.7MPa

- Operation system : 10’’ touch screen

- Dust collector Dia.xN : 125mmx4

- Total power : 24 Kw

- Approx. weight : 3670 kg

- Overall dimension : 7700*1450*1650 mm

PROCESSING AND OPERATIONAL UNITS:

Pre-milling: This unit prepares the workpiece edge before gluing, creating an optimal basis for the binding effect. It uses a diamond cutter and two pneumatically controlled 3.7 kW motors, running at 12,000 rpm.

Pre-Heating: This feature heats the workpiece edge to allow the glue to melt well during gluing. Therefore, this machine is suitable for working in wet or cold zones.

Pre-melter Gluing System: The top-mounted glue tank is for maintaining appropriate glue volume and saving heating-up time, while the small glue pot at the bottom maintains the fresh condition of the glue by avoiding carbonization and vulcanization of glue resins. A 60mm high gluing roller works best in mass production and for long parts. Liquid level sensor detection device controls glue amount precisely. The system has a sliding seat for an optional changeover to a PUR device.

Snipping: The edge tape is finely cut by using an air cylinder with an electric-controlled switch.

Pressure Rollers: This unit features a pre-pressure roller with a diameter of 100mm, working in conjunction with four post rollers to tightly secure the edge tape onto the edge surface.

End Trimming (End Cutting): This unit removes extra edge tape on the front and back using a linear guide way structure at an angle of 45 degrees. Driven by two 0.35kW motors, it uses high-precision linear guides for extremely high repeatability.

Rough Trimming: The unit features dual high-powered motors and two milling cutters, each guided by durable steel positioning guides.

Fine Trimming: R1.5 Cutter with pneumatic auto tools adjustment: This unit uses R1.5 milling cutters and features two position tool adjusting. This allows the operator to switch between thin edge and thick edge settings with just one click, saving adjustment time.

Corner Trimming: R1.5 Cutter: This tool is designed to round off sharp corners into an arc with an R radius. It uses a planar linkage with two R1.5 tools. The angle of rotation automatically changes through an electric sensor.

Scraping unit with two position pneumatic auto adjustment: The edge is scrapped by the R1.5 cutters of this unit to make the edge banding more beautiful. It has two position tools adjusting, which allows a quick switch with one click from thin edge to thick edge.

A spraying device applies a release and cleaning agent to the surface of the workpiece to minimize glue adhesion. Before buffing, a cleaning agent is applied to help minimise any potential glue lines.

Buffing: This is the last step, using a dual screen cloth structure to make the edge shining, more stable.

CONTROL, MAINTENANCE, AND SAFETY FEATURES:

This Automatic Edge Banding Machine also includes specialized systems for operation, safety, and maintenance:

Control System: The operation of the Edge Banding Machine is through a 10-inch touch screen that has an intuitive and simple interface, allowing independent control over each component for testing and commissioning.

Energy Saving: Automatically activates stand-by mode when the machine has been idle longer than a preset time, and production can restart by a single click. Remote switch &

Indicator light: A remote switch offers the utmost in convenience for starting or stopping the machine during the process, while an indicating light shows operation status at a glance.

Lubrication System: The lubrication pump makes everyday maintenance easier. It requires just the pull of a handle to grease the guiding rail. Safety devices include a Feeding Protector that monitors abnormal operation, work piece thickness detection to stop the conveyor in case of thickness over the limit, an Interval feeding detection system to hold proper spacing, and an E-STOP button.