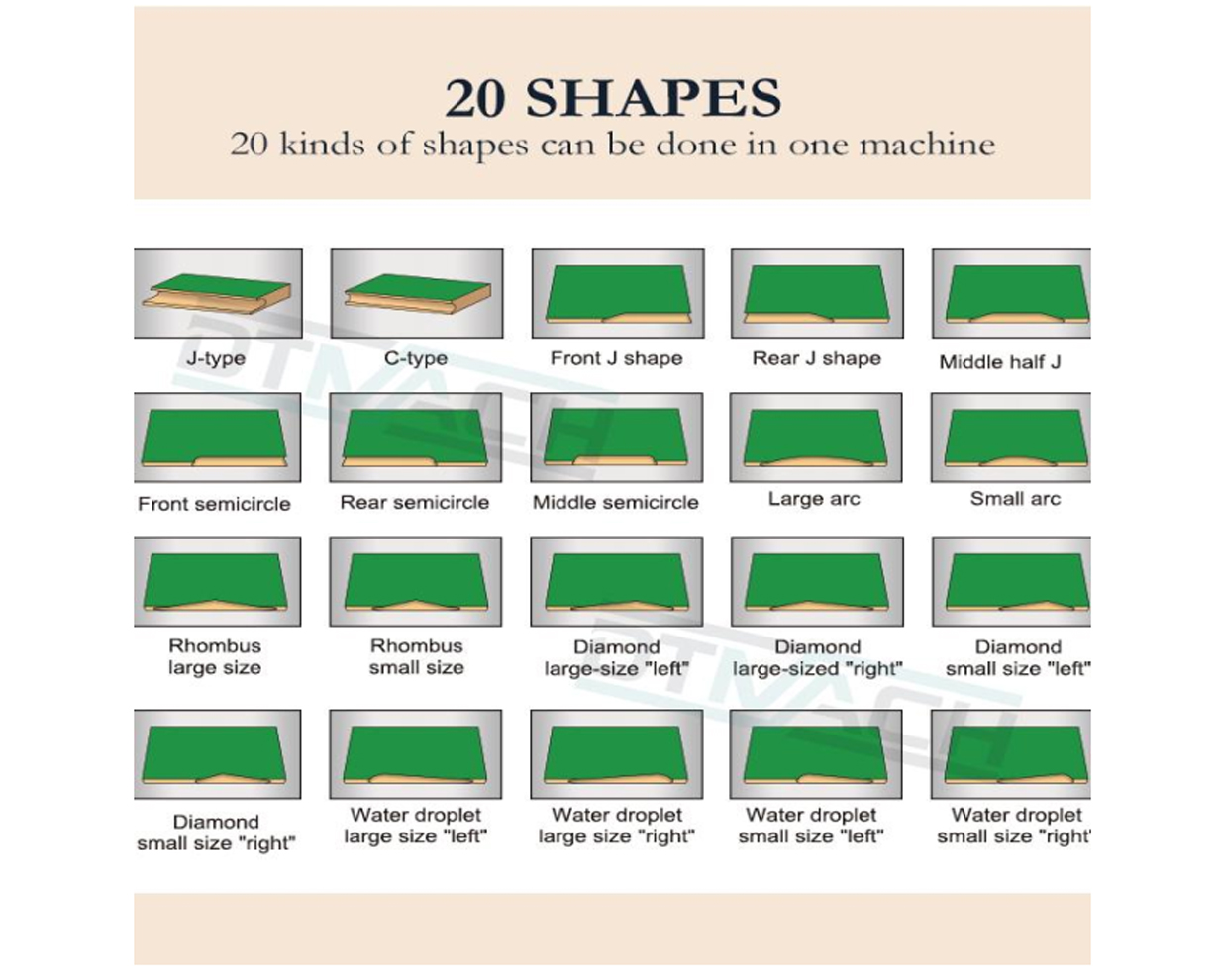

Automatic Soft Forming Edge Banding Machine JC500 (20 Shapes)

Machine Parameters

- Voltage: 4150v / 50 hz / 3 phase

- Total Power: 55 KW

- Air Pressure: 0.6-0.8 Mpa

- Dust: φ 150 mm × 3 pcs

- Feeding Speed: 9 m/min

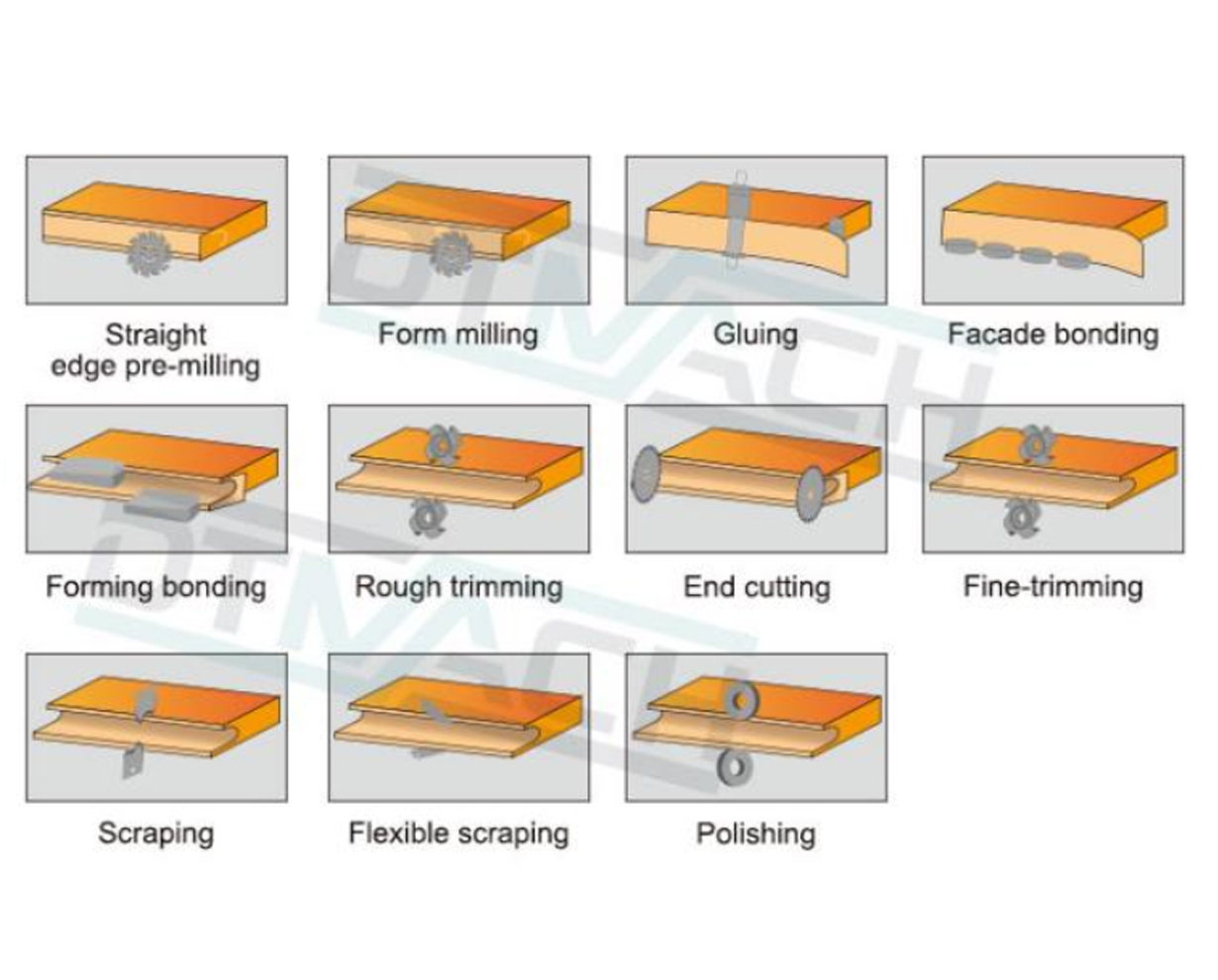

Units

- Straight edge pre-milling

- Form milling

- Gluing

- Facade bonding

- Forming bonding

- Rough trimming

- End cutting

- Fine-trimming

- Scraping

- Flexible scraping

- Polishing

Edge Banding Strip

- Strip thickness: 0.52 - 0.75mm

- Strip Width: 35-75 mm

- Strip Material: PVC

(matte surface instead of glossy surface)

- Panel Thickness: 18 mm/22 mm/25 mm

- Panel size: ≥380*150 mm

Precise mold

- Achieve accurate milling error ≦ 0.2mm

Conveyor

- Feeding Speed: 9 m/min

- Motor Power: 4KW

- Encoder meter counting, precise movement

- Automatic lifting and lowering of pressure beam

Pre-milling

- 4 pcs diamond milling cutters

- 1,2 milling motor power: 2.2kw

- 3 milling motor power: 12kw

- 4 milling motor power: 7.5kw

- Servo motor power: 0.75kw*2

- Lift motor power: 0.75kw

- The brush removes debris and preliminarily cleans the board.

Glue

- Glue type: Eva glue

- Glue pot: 2600ml

- One-click glue removal for easy cleaning

- Three limits ensure stable running of the strips

- The centrifugal fan cools down the edge banding to ensure

smooth tape feeding.

Pressing assembly

- 2 sets of facade pressing

- Bottom direct pressing and 2 sets of baking lights

- 14 components of pressing, step by step, air pressure can be adjusted individually

- 1 set of auxiliary pressing