Nanxing CNC Nesting Machine NCG3021LE with [AL+UL | 12KW Spindle | V10 Drill | FCC+Editor | Pressure Roller]

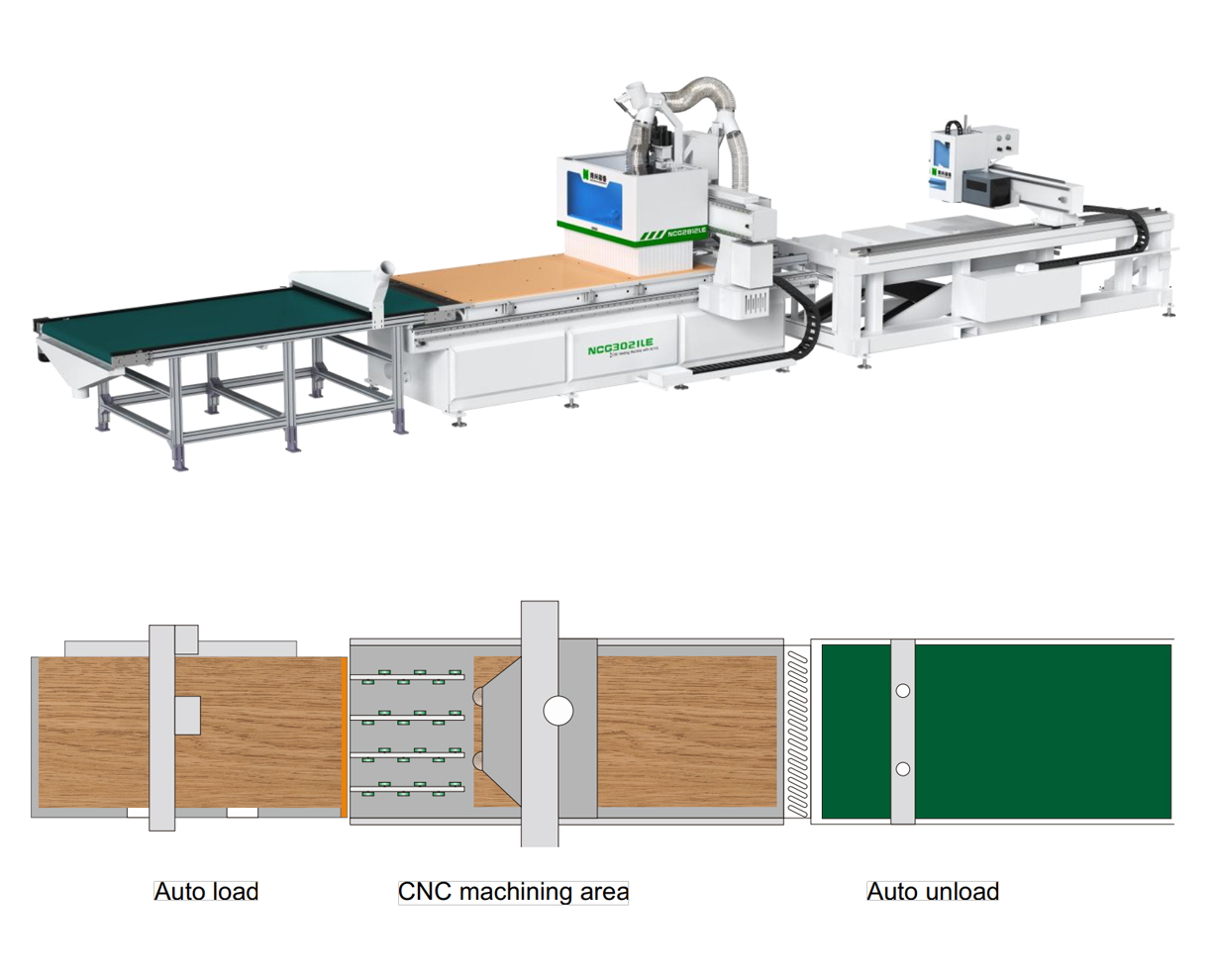

This advanced machining system seamlessly integrates three core stages: automatic loading with integrated labeling, precision CNC processing, and automatic unloading. It is engineered for the efficient execution of critical panel operations, including milling, grooving, and drilling.

An integrated labeling system enables the tracking of board information down through downstream equipment, such as edge banders and drilling machines, via barcode scanners for seamless integration into a workflow. This enables a manufacturing line that is connected, efficient, and error-resistant.

1. End-to-End Automation with Improved Material Handling

Feature: A fully integrated automatic loading and unloading system, complete with a pressure roller for superior board control.

Advantage: Creates a seamless, hands-off production line, ensures panels perfectly flat and stable during transit and processing.

Benefit: Maximizes productivity with guaranteed consistency of quality, since there is no manual handling and material shift and lift cannot occur, for flawless output with minimal labor.

2. High-Speed Drilling and Precision Machining

Feature: High-speed gantry 100 m/min with a V10 drilling block for dedicated high-precision boring operations.

Advantage: Milling and drilling can be performed simultaneously, which drastically shortens the cycle time while providing perfectly vertical and accurate holes.

Benefit: Dramatically increases throughput for intricate parts that require both profiling and drilling. This is done with a superior finish and accuracy in one setup.

3. Powerful Processing with Intelligent Control

Feature: Robust 12KW high-frequency spindle and the FCC + Editor software suite on the SYNTEC control system.

Advantage: Provides immense cutting power for heavy-duty jobs and offers an intuitive, graphical interface for easy toolpath verification, nesting, and machine control.

Benefit: Handles even the most challenging materials with ease and simplifies operation, reducing programming errors and training time for faster, more reliable production.

4. Better Work holding and Process Integration

Feature: Optimized vacuum table with a total of 7 zones evenly distributed adsorption force. Even small workpiece are held firmly

Advantage: Provides flexible and powerful suction to securely hold a wide range of workpiece sizes and materials, while automatically labeling each part for identification.

Benefit: Eliminates workpiece movement for guaranteed accuracy, and enables seamless traceability with the ability of downstream machines to automatically read barcodes for a connected, error-free workflow.

5. Engineered for Maximum Uptime and Reliability

Feature: Dust-sealed independent electrical cabinet, automatic lubrication, and a heavy-duty welded frame.

Advantage: It actively protects sensitive components from contamination and ensures long-term structural integrity at high-speed operation.

Benefit: Protects your investment and minimizes unscheduled downtime to ensure the machine is able to perform day-in and day-out with minimal operating costs.

TECHNICAL DATA

- Control system : 1 spindles controller

- Working range : X-axis: 3,100 mm

- Working range : Y-axis: 2,100 mm

- Working range : Z-axis: 200 mm

- Working table size : 3100 x 2100 mm x H900mm

- Max. traveling speed : X-axis: 100 m/min

- Max. traveling speed : Y-axis: 100 m/min

- Max. traveling speed : Z-axis: 20 m/min

- Main spindle : 12KW*1 , 2400rpm / ER32

- Servo motor : X axis: 1.3kw*2

- Servo motor : Y axis: 1.3kw

- Servo motor : Z axis: 1.3kw

- Vacuum pump : 3*7.5kW Suction flow rate: 250 m3/h

- Dust collector outlets are 1*150 Dia and 3*125 Dia

- Speed rate : 30 m/s

- Air pressure required: 6~7 kg/cm2

- Power supply Voltage: 415V, 3-phase / 50Hz

- Total Power Supply 39.7kW

- Floor space LxWxH: 11,800x3,350x2,500 mm

- Net Weight : 6000KG