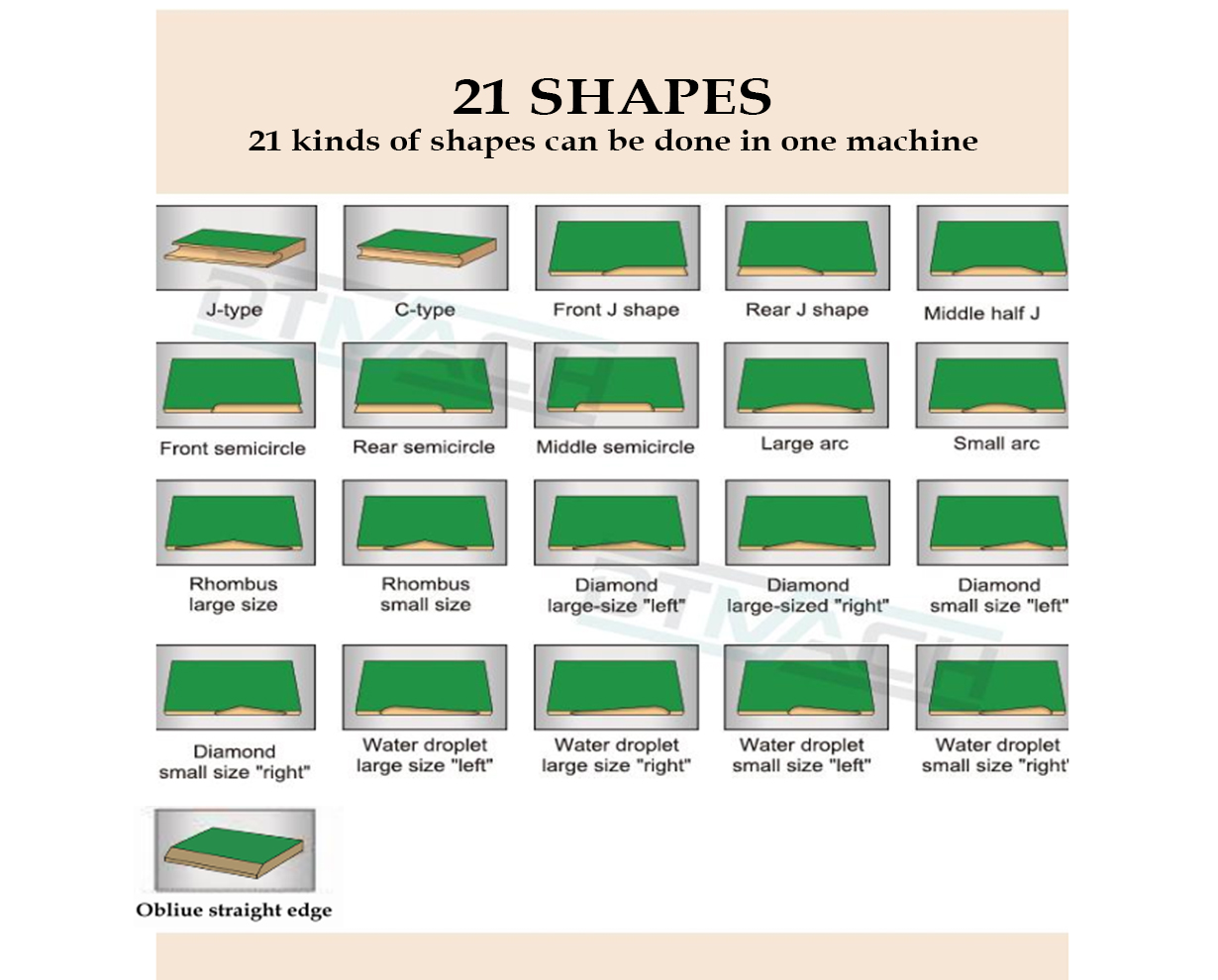

Automatic Soft Forming Edge Banding Machine JC510 (21 Shapes)

FEATURES

Conveyor

- Motor Power 4KW

- Encoder meter counting, precise movement

- Automatic lifting and lowering of pressure beam

Pre-Milling

- 4 pcs diamond milling cutters

- 1,2 milling motor power: 2.2kw

- 3 milling motor power: 12kw

- 4 milling motor power: 7.5kw

- Servo motor power: 0.75kw*2

- Lift motor power: 0.75kw

- The brush removes debris and preliminarily cleans the board. Secondary edge sealing can be performed to reduce graininess

Glue

- Glue type: Eva glue

- Glue pot: 2600ml

- One-click glue removal for easy cleaning

- Three limits ensure stable running of the strips

- The centrifugal fan cools down the edge banding to ensure smooth tape feeding.

Pressing Assembly

- 2 sets off acade pressing

- Bottom direct pressing and 2 sets of baking lights

- 14 components of pressing, step by step, air pressure can be adjusted individually 1 set of auxiliary pr i g

Rough Trimming

- Rotary trimming

End Cutting

- Multi-tooth silencer saw blade, low noise

- Pressure can be adjusted individually

Fine Trimming

- Refinement of R angle

- Adjustable up, down, left and right

- servo motor

Scrapping

- Remove glue lines and knife marks left by trimmers

Polishing

- Scrape off excess glue marks

TECHNICAL SPECIFICATION

- Voltage: 415 v / 50 hz / 3 phase

- Total Power : 55KW

- Air Pressure : 0.6-0.8mpa

- Dust Dia : 150mm x 3

- Feeding Speed : 9m/min

- Strip thickness: 0 .52 - 0. 75mm

- Strip Width: 35-75 mm

- Strip Material: PVC

- Panel Thickness: 18 mm/ 22 mm/ 25 mm

- Panel size: 380*150 mm

- Achieve accurate milling error : 0.2mm