- ABOUT

- BRANDS

- PRODUCTS

- Woodworking Machines & Consumables

- Sanding Machines

- Presses

- Saws

- Routers

- Edge Banders & Trimmers

- Multi Boring Machines

- Surface Planers & Thickness Planers

- Combination Machines

- Spindle Moulders

- Post Foming Machines & Soft Forming Machines

- Wood Lathes

- Tenon Mortisers

- Veneering Cutting & Splicing Machines

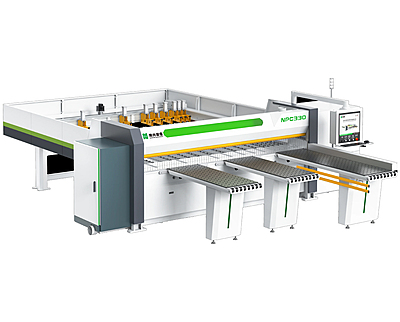

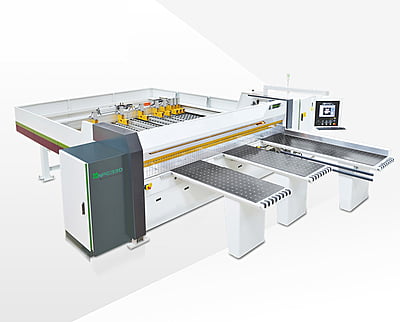

- Automated line for Custom and Mass Furniture Production

- Power Tools

- Sawing

- Portable Edge Banding Machine

- Drilling & Screwdriving

- Portable Jointing Machines

- Woodworking and Metalworking Clamps

- Hand Planers & Portable Thickness Planers

- Hand Routers & Trimmers

- Surface Finishing Tools

- ACP Fabrication Tools

- Drywall Construction Tools

- Multi Tool Oscillators

- Workplace Organisation

- Portable Dust Extractors

- Dust Collector

- Paint Booth, Spraying Machines & Clean Rooms

- Material Handling Equipment

- Air Compressors

- Woodworking Machines & Consumables

- PACKAGES

- More

Currency