Nanxing

Nanxing

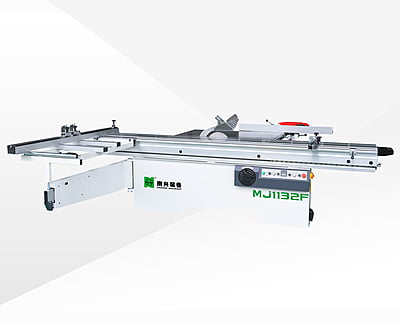

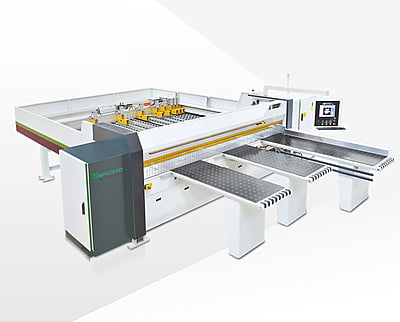

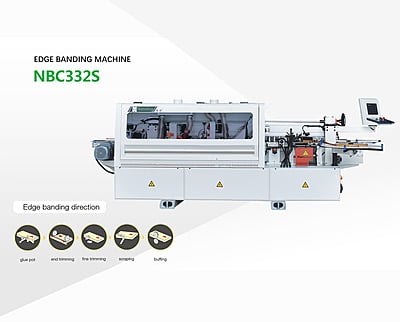

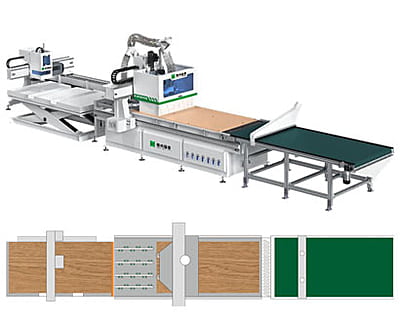

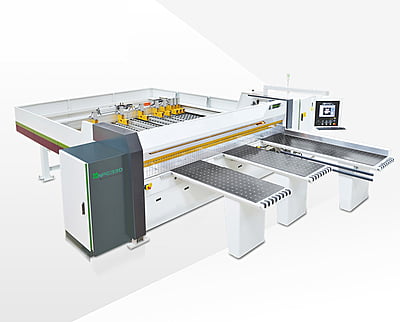

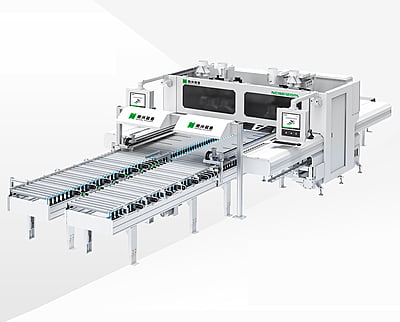

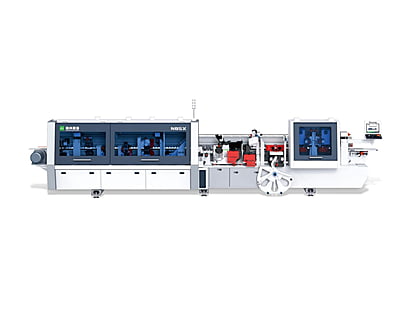

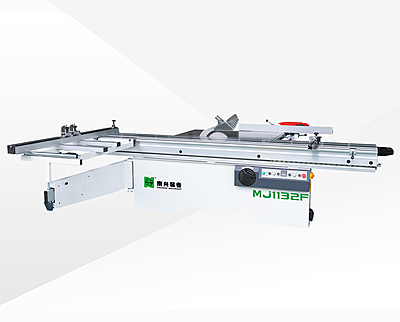

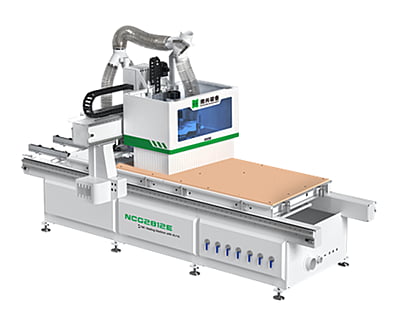

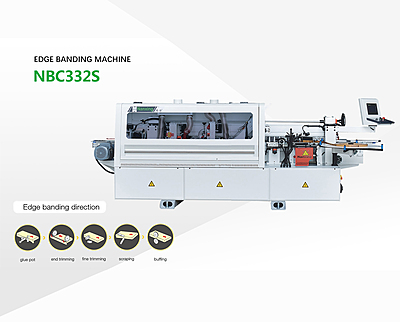

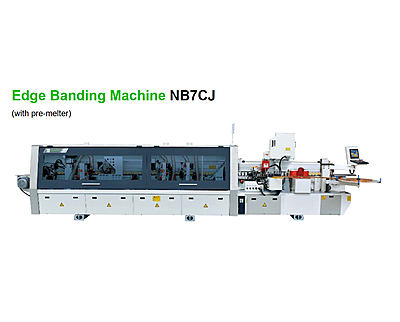

Caple has tied up with Nanxing; why change its approach to adding a major Chinese brand to Caple's portfolio that has thrived on European brands? China is not at India's doorstep but Europe's doorstep. It is knocking hard, but Europe seems not to be listening. Chinese are different from how they were ten years back; they have improved in quality and service. If you call a Chinese on a Saturday evening, the sales and service department will respond, but the European will not after Friday afternoon. The Chinese would still work 50 hrs per week, whereas Europeans would work only 35 hrs weekly. The Chinese still target doubling the revenue every three years. This is a CAGR of 27%. Europeans cannot even imagine this growth. This shows that even after being the factory of the world, they are not complacent, and there’s a hunger in the country to learn and grow.Europe was the core of innovation till now, but the first investment to go away is in R&D when you don’t grow fast. This R&D is now happening in China. Look at the configuration of machines: the CNC beam saws, edge banders and CNC boring are minimum double the productivity. Let me quantify this for you. 8x4 board = 32 sq feet-15% waste = 27 sq feet x gross margin consider Rs 100 just for calculation sake = 2700 per board x 300 days = 8.1 lacs / board / year. This means one board can have a contribution margin of 8.1 lacs/year. They have focused on increasing the per sq feet business. Imagine that you can scale with ten boards extra per day = 81 lacs per year of additional gross margin in the same space, labour, energy and cap ex, which means your ROI is super high. This is scale. This is efficiency. It is not that Europe doesn’t have this technology, but it is 3-4x expensive. This technology is not rocket science anymore like it was 20 years ago. These are mostly cabinet-making machines.

How are the Chinese machines so cheaper than Europeans? The Europeans customised their machines for batch size one with open configuration, and the Chinese have commoditised this with a closed configuration.

The European brands have inspired the world. I hope they change the strategy of moving to a higher configuration but keep the production price low. This can only happen if they invest in manufacturing in India or China. In China, the European brands are losing ground even after the manufacturing base, demotivating them to invest big in India.

What do you think about made in Indian machine tools? Unfortunately, only 1-2 European brands have seriously invested in Indian manufacturing, but the configuration is still low-productivity and low-speed, which is suitable for small workshops. Still, the machine configuration differs from that required for larger workshops or big factories. I am a hardcore nationalist, but the Indian brands, unfortunately, have failed to build manufacturing capabilities and forget about scaling in capacity. A few Indian brands that claim to be made in India are buying and white-labelling from China. This made-in-India tag is misguiding the customers. The mother machines required to make machines require high precision and are either Japanese, German or Taiwanese. Nanxing has invested nearly a billion USD in 200+ Mazak, SMK, Trumpf, etc. These are mother machines to manufacture machines. This shows that all the components are machined in-house and not outsourced, and quality and production are controlled. They are producing 10x the volume of large European suppliers and doubling every three years.

The industry's future is hybrid, with E-commerce, brick-and-mortar stores and site work coming together. It is time for Industry 5.0, with people being a dimension complemented by data-capturing machines and decision-making made easier with AI. The software solutions that we are now offering includethe integration of ERP with the designer on the front end at the store, designs that are pre-engineered yet customisable, and ERP. A single software should be able to bring in data from multiple stores or dealers, render on the cloud, should be able to have a manufacturing engineering system MES, be able to have advanced production planning APP and be able to have sorting, packaging and warehousing optimisation. It should have cloud optimisation and integration (API) amongst all modules and post-processers with machine manufacturers. We can offer this proven software integration with Nanxing.