MAIN FESTURES

COMPACT TO PROVIDE MORE FLOOR SPACE

DIAMOND-SHAPED BELT: NO SLIPPING OF THE WORK PIECES

TECHNICAL DATA:

- working width [mm] : 1350

- min/max. working thickness [mm] : 4-170

- sanding belt width [mm] : 1370

- sanding belt length [mm] : 2150

- main motor power [kW (HP)] : 11 (15)

- Feed belt motor power [Kk (HP)] : 0,45/0,8 (0,6/1,1)

- Feed Speed [m/min] : 4.5,9

GENERAL FEATURES:

Base and working table

* steel structure with electric cabinet on the machine front

* sanding belts introduction from the machine left side

* powered adjustment of working thickness

* main motor positioned inside the base

Electrical equipment

* electromechanical keyboard positioned on the machine front side

* automatic star-delta start of the main motor

* overload protections on the motors

* IP54 motor protection

Emergency and safety devices

* safety micro for overthickness

* automatic brake for rapid shutdown of the operating group

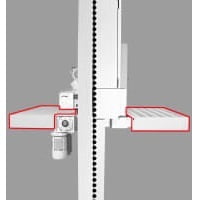

* hand-safety emergency device in the infeed panel area

* front and rear emergency pushbutton

* padlockable main switch

* automatic emergency stop machine for:

- sanding belt breaking

- not-tensioned sanding belt

- lateral outplacement of sanding belt

- absence of compressed air

- overload on main motor

N.B. The machine with standard configuration is supplied with 400 Volt 50 Hz and 3-phase version + neutral + earth.

When the 400 voltage supply has not the neutral phase, it is necessary to select the single-phase transformer, foreseen on the price list.

The same transformer has to be selected also when the machine is supplied with voltages higher than 400 volt, independently from the neutral phase presence.

The machine supply with 220 or 230 voltages (50 or 60 Hz) is foreseen in the price list with an additional cost.

BASIC MACHINES STANDARD EQUIPMENT

- R160/85 - 85Sh rubber-coated calibrating roller, 160mm diameter, in 1st position

- R250/45 - 45Sh rubber-coated sanding roller, 250mm diameter, in 2nd position

- Stiff pad with manual adjustment of working height

- 11 kW (15 HP) single main motor

- Electronic ammeter on main motor for readout of absorbed power

- Electronic readout of working thickness

- Electronic oscillating of sanding belts

- Rubber-coated pressure rollers

- Infeed anti-kickback vertically pivoted roller on 1st operating group

- 60 Sh rubber feed belt

- Infeed/outfeed workpieces support rollers with two rollers

- Feed belt speed with 2-speeds variable feed motor ( 4,5 / 9 m/min)

- automatic device for feed belt tracking and tensioning

444416 "A" version for RR

complete with:

- on/off pneumatic selector of the 1st roller

- on/off pneumatic selector of the 2nd roller

electronic positioning for working table

230380 Floating pressure shoe - 1st position

complete with steel linings and rubber-coated pressure rollers

230381 Floating pressure shoe - 2nd position

complete with steel linings and rubber-coated pressure rollers

230382 Floating pressure shoe - 3rd position

complete with steel linings and rubber-coated pressure rollers

333151 Infeed and outfeed support rollers for long and short workpieces

The infeed support rollers is equipped with 5 idle rollers and the

outfeed one is equipped with 1 powered roller and 4 idle rollers

222391 Vacuum table equipped with 3 kW (4 hp) fan motor

and working table and feed belt punched

222392 Fan silencer

470735 Oscillating belt cleaning blower on the 1st group

The device is complete with:

- electronic tracking

- timer activated directly on working piece

- exhaust hood

- filter and pressure adjustment

470736 Oscillating belt cleaning blower on the 2nd group

The device is complete with:

- electronic tracking

- timer activated directly on working piece

- exhaust hood

- filter and pressure adjustment

411857 Belt feed with1,5 kW (2 hp) mechanical speed variator

with adjustable feed belt speed from 3,5 to 18 m/min

624440 10” Control panel with “eye-S” integration software

For machines without elastic or electronic sectional pad.

- 10” touch screen monitor

Machine control features:

- control of main operating groups;

- control of on/off positioning for working groups;

- control of the feed by inverter;

- working thickness control;

- sequential automatic start up of main motors;

- abrasive belt speed control adjusted by inverter;

- blowers timing control for belts cleaning and for rotating blowers of outfeed panel cleaning;

- machine control in manual or with working programs

which can be configured by the operator. It is possible to

save 999 working programs;

- machine report (working and stand by hours);

- machine damage alarms control;

- maintenance manual;

available languages IT, EN, FR, ES, DE.

975074 2-Speed main motor 15 kW (20 hp)

(9/18 m/sec.)

085879 Pallet + nylon - 135 version

999999 Option for Veneer sheet sanding

*Rubber conveyor belt (60 shores) with flat profile

* Dedicated drilling of the work-top for vacuum device

* Extended and bevelled steel sliding pads

* Steady pressure bars in 2nd and 3rd position (tightened by

means of disc springs) * Additional steel sliding pad at the

outfeed of the 3rd pressure bar

* Special workpieces entrance (shaped) and special “hand-

safety” device (stiffed and leant backward) to make easy the

feeding of bowed sheets

* Tampico linear brush for conveyor belt